PILING AND FOUNDATION SERVICES

At EXOFOR, we are dedicated to providing top-notch deep foundation services for a wide range of projects, including residential, commercial, and industrial developments. Our team of experts has extensive experience in the foundation industry and uses the latest technology and equipment to ensure that your deep foundation is installed with precision and efficiency.

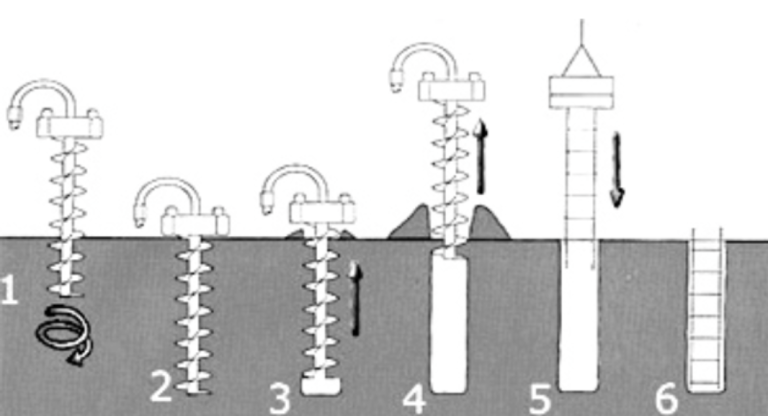

Auger Cast Piles

EXOFOR use the ACP technique (Auger Cast Piles) which is today one of the fastest growing techniques for foundation in the world. The Continuous Flight Auger method allows the construction of piles with minimal environmental disturbance. It is one of the quietest forms of piling, and is suitable for most types of ground conditions. A hollow-stemmed continuous flight auger is rotated into the soil to the required depth using a top mounted hydraulic motor, no casing is required. A high slump concrete mix is pumped down the stem of the auger and the pile is formed as the concrete is pumped into the pile bore whilst the auger is slowly raised, lifting the spoil on the flights. Normal pile diameters of 300 mm to 900 mm can be constructed up to a maximum depth of 22.50 m. Depending on ground conditions, working loads of up to 2000 kN can be carried.

Auger Cast Piles can be used as:

The superstructure load is transferred to the soil through friction between the pile surface and the soil.

The superstructure load is transferred through the pile tip into a hard stratum of soil or rock.

Hydrostatic or other uplift forces are resisted through a full-length tendon embedded in the grout column.

of a continuous auger cast curtain wall in temporary or permanent shoring systems and below-grade walls.

diagonal tie-back in auger-cast curtain walls, beams and lagging walls, and sheet pile walls.

Advantages of Auger Cast Piles:

LESS NOISE

NO OBJECT VIBRATION

NO CASING REQUIRED

CAN BE INSTALLED IN LIMITED HEADROOM CONDITIONS

Micropiles

Drilled micropiles were invented in Italy in the 1950’s as a means to underpin sensitive historic buildings. The pile, called the Palo Radice or root pile, was a small diameter cast-in-place, lightly reinforced drilled pile, developed by the Italian geotechnical construction company, Fondedile. Drilled micropiles can be installed in a wide range of soils from non-cohesive, poorly graded granular soils, to cohesive plastic clays.

Uses for Micropiles

- Structural Foundation Support

- Structural Underpinning

- Soil/Slope Stabilization

- Excavation Support

- Seismic Retrofit

- Arresting Structural Settlement

- Resisting Uplift/Dynamic Loads

- Excavation Support in Confined Areas

- Reticulated Pile Wall

Advantages

- High bearing capacity

- Measure 6 to 12 inches in diameter

- Minimal disturbance/vibration to adjacent structures

- Capability to penetrate subsurface obstructions

- Design loads from 1 to 200+ tons

- Can be readily designed for tension/uplift loads

- Appropriate for a wide range of ground conditions

- Suitable for low headroom and restricted access

- Low noise

Driven steel and Pre-Cast piles

A driven pile is a relatively long, slender column, provided to offer support or to resist forces, made of preformed material having a predetermined shape and size, which is installed by impact hammering, vibrating or pushing into the earth. This pile consists of pre-manufactured structural shapes built to precise tolerances utilizing high strength materials and reliable quality control. The wide variety of materials and shapes available for driven piles can be easily fabricated or specified for high structural strength, resulting in substantial savings in foundation costs. The design, installation and quality assurance that are a part of each driven pile combine to eliminate guesswork and produce a known, reliable and cost effective product that can accommodate a wide variety of subsurface conditions. The most common use of the driven pile is in deep foundations, they can also be utilized in other applications such as pile- supported embankments, sound wall barriers, retaining walls, bulkheads, mooring structures, anchorage structures and cofferdams.

Advances

- Do not corrode or rot.

- Stable in squeezing ground.

- Pile material can be inspected before piling.

- Construction procedure unaffected by ground water.

- Can increase the relative density of a granular founding stratum.

- Minimal site preparation

- Can be installed successfully in most ground conditions including

peats, soft clay, and loose sand where some other techniques are

unsuitable. - Design loads up to 1,000 tons

- Usually the fastest deep foundation

- Driven pile installations usually produce no spoils for removal and therefore no exposure to, or costly disposal of, potentially

hazardous or contaminated materials. The site is left clean and ready for the next construction activity.

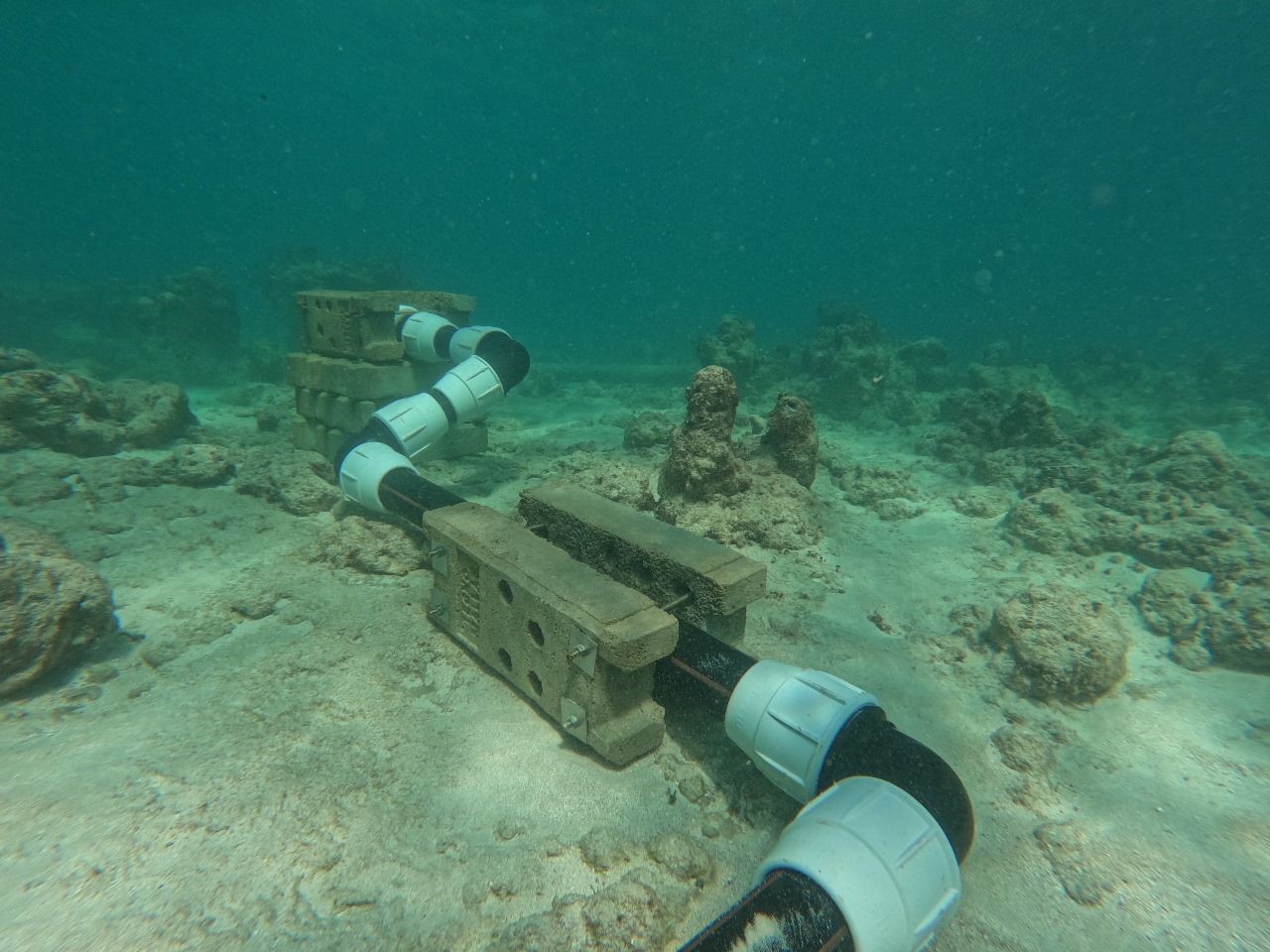

Sheet Piles and Docks

Sheet pile walls are constructed by driving steel sheets into a slope or excavation. They have an important advantage in that they can be driven to depths below the excavation bottom and so provide a control to heaving in soft clays or piping in saturated sands. Sheet piles are more costly and less adaptable to hard driving conditions particularly where boulders or irregular rock surfaces occur.

There are 3 main types of sheet pile walls:

- Cantilever: One main advantage of cantilever

sheet pile walls is that they can be pulled and

reused. - Anchored: Well-constructed anchor walls

undergo less lateral deflection than braced walls

and so provide better control of back slope

subsidence. - Propped: They can be designed to have fixed or

free earth support at the bottom and derive their

stability from the props.

We also offer a range of related services, including soil stabilization and ground improvement.